Compressed Air Treatment

|

Home → Compressor Filters → Spare Parts

Compressed Air Treatment Products

Compressed air treatment products from NEW

FILTER will help you keep your air compressors performing at their best. Choose

from a huge selection of pressure sensors, filters, oil/water separators, and

many more.

Properly treated compressed air, and the

right air dryer, will improve productivity, system efficiency, and product or

process quality.

The condensate in the compressor often

becomes a cause of unstability of the device, the appearance of oxidation in

the line, freezing of pneumatic valves, bubbling paint on the work piece, and

the moisture in the container and packaging. It's worth noting that the longer

the line from the compressor unit to the operating element (air cylinder, a

sprayer, pneumatic), the greater the volume of condensate accumulate.

Discover the most interesting offers! Discover the most interesting offers!

To ensure perfect cleaning of the

environment in the system of filing and preparation of compressed air, and the

result of the compressor, it is necessary to purchase special filters and

dehumidifiers. You can buy them at managers NEW FILTER.

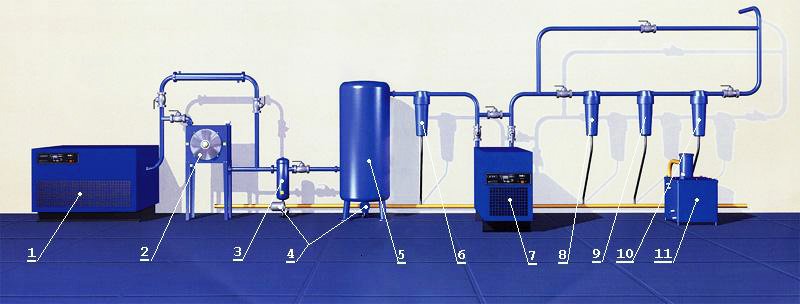

Typically the system

includes the following elements:

The components of the system are follows:

- Compressor - screw or piston, which is used as a

source of compressed air. The type of the device and its

location the amount of condensate produced will depend on which will have to be

withdrawn from the system. The compressor is mounted on the operating segment,

the greater the amount of moisture is formed. Therefore, compressor cleaning

becomes a priority.

- Cooler - needed to reduce the

temperature characteristics of the compressed air which is supplied from the

compressor to the system. This is an important process,

because stream heats up when compressed.

- Separator - compressed air cleaning

device for separating condensate formed in the pneumatic system. It

is specifically designed based on the centrifugation principle, which allows

removal of working medium to 99% moisture and aerosols.

- The thermodynamic steam trap - a device that is used

to drain the collected water at each stage of the compressed air cleaning

system. There are automatic (by filling),

semi-automatic (by timer) and manual assembly.

- Air collector - multifunctional

mechanism. It is used to smooth out the compressed air

pulses, which is fed by the compressor in the system. air collector also acts

as a compressed air accumulator, ensuring smooth operation of the mechanism

under pulse air consumption.

- Air

filters. These products are used in different versions, which depend on the

source of compressed air. Coarse filter (dust filter) guarantees the cleaning

of solid particles (up to 10 microns). The pre-filter provides the residual

content of impurities of up to 5 microns.

- Dry compressed air dehumidifier allows the removal

of moisture vapor resulting from said compressed air to the dew point. The

principle of operation is simple: when the medium enters into the air

distribution system for cooling the water vapor is converted into condensate.

When the temperature indicator at 25 ° C and a relative humidity of 75% the

standard compressor unit (capacity 20 m3 / min) produces 165 liters of water

per 1 shift (8 hours), unless it is equipped with after-cooler. However, even

after processing and after-cooler drier air in the pipe is fed more than 50

liters of water per 1 shift, which significantly affects the final result.

- Pre-filter - a device for

filtration of solid medium of microparticles (size less than 1 micron) and oil

impurities (up to 0.1 mg / m3). Buy pre-filter

can at consultants, referring to the "Contacts" section.

- Fine filter - coalescing filter for removing

solids from the working environment of the microparticles (0.1 microns) and oil

impurities (up to 0.01 mg / m3). This mechanism is

installed after the main filter cleaning. NEW FILTER offers the opportunity to

buy fine filter at an affordable price.

- Carbon filter - designed for removing odors. Particulate

residue is not regulated, vapor content of not more than 0.008 mg / m3. This

filter is typically mounted on almost all types of food manufacture.

- Separator - is used to separate the

droplets condensate (oil - water emulsion), drained of all structural

components of the system and recycling. The separator

allows you to collect all the oil and properly remove it, and return the water

to the sewer system for further purification.

Why choose us?

..........

|

Unique product |

|

40% savings |

|

Stability |

|

Trust |

|

Individual approach

|

|

|

|

|

|

|

|

|

|

|

Official dealers of Sotras, Noitech, Filtrec

|

|

Exclusive partnerships with manufacturers give us the possibility to deliver the goods at the lowest prices |

|

6 years of successful work, hundreds of satisfied clients and our own production

|

|

We do not have occasional customers - everyone becomes part of a team of leaders! |

|

Individual approach for each client |

|