Home → Compressed Air Treatment

Coalescing Filter Elements

Coalescing

filters are used for separation of higher grade, as compared with other

purification and filtration systems. These filter elements can reduce the

concentration of oils, aerosol-type liquid in a gaseous medium to a level of 0,003

ppm, and ensure the removal of 99.99% of solid microparticles.

NEW FILTER delivers coalescence filters

PALL, which uses a unique filter material cartridges and special design that

allows you to work with the increased load, cycling less cartridges in the

system.

Pall system

presents data in both vertical and horizontal design. AquaSep® type systems are

used for separation (liquid / liquid), and a series PhaseSep can serve as a

coalescer type (liquid / gas).

|

|  |

|

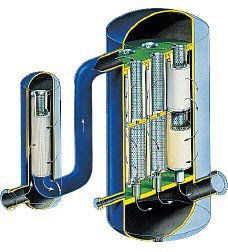

Vertical

configuration of coalescer.

The liquid comes out the bottom

left, and the purified medium to the right.

|

|

Horizontal

configuration of coalescer.

Purified

from impurities phase goes from the top to the right and removed the dirt right

from the bottom.

|

What does coalescing filter for?

Coalescers are designed for ultra-clean

gaseous and liquid media from the droplet, mechanical fractions. Moisture

condensation formed by spraying due to obstacles in the gas stream.  The body

design of the product is non-regenarated replaceable cartridge. It is effective

as the second stage of filtration elements after the cyclone.

The body

design of the product is non-regenarated replaceable cartridge. It is effective

as the second stage of filtration elements after the cyclone.

Highly efficient coalescence filters (gas /

liquid) medium ensures removal of the liquid droplet size of 0.1 micrometers,

and also provide a small pressure differences on the filter element.

The advantage of using coalescer - is high

speed flow without repeated removal drops.

Cleaning the gaseous medium from the liquid

impurities in the coalescer is due to the ability of the filter media to

connect liquid aerosol smallest size (0.3 microns) to larger ones. Thus there

is a further accumulation and removing them through the drainage system.

Coalescing filter: working principle

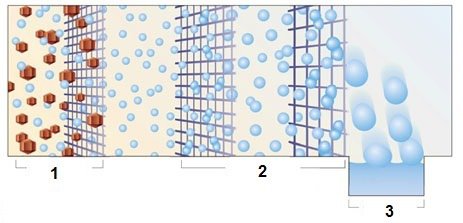

The

processes in the diagram:

- Solid

particles are removed by the filter material.

- Little drops

of water coalesce into larger passing through the filter layers coalescer.

- Under the

influence of gravitational fields of large drops separated and deposited.

Coalescer principle of operation is as

follows: the incoming flow passes through the coalescing unit - thin-layer

corrugated plate, resembling a honeycomb. This material provides sintering

petroleum oil in the beads and repels water. As a result, moisture is separated

from the oil.

When enlarging droplets increases their

speed ascent to the surface. Due to the inclined corrugated plates provide

maximum contact between the cleaning medium with a modulus that promotes

intense increase in particle size.

Then, the separated oil particles float

upwards, forming a layer on the water surface. When it flows through the module

creates a vibration, resulting in oil spills float and suspended solids settle.

Used filter elements should be replaced

with oil pollution. replacement frequency depends on the initial level of

contamination of waste water.

Technical characteristics of the gas

coalescing filters

- efficiency of gas filtration of liquid

drops - 95% -99.95% (depending on the type of the filter);

- filtration efficiency of the gas flow

from the solid fractions - 95% -99.95% (depending on the type of the filter);

- filtration efficiency gas medium from

liquid and solid contaminants larger than 1 micron - 98% -99.99%;

- volumetric efficiency: gas - up to 50

million m3 / day of liquid - up to 250 m3 / hour.

- residual volume of liquid and solid

particles in the purified gas stream - 1 mg / m3 or less;

- temperature: -70 °C min, max + 150 °C

(as solid particles) and to + 90 °C (liquid).

Important! In order to provide increased

strength at the maximum operating temperatures of calculated coalescer and its

use in hostile environments, it is recommended to install perforated metal

exterior frame. It is recommended to use a spring mounting of cartridges in the

lander place to provide the necessary seal.

Why choose us?

..........

|

Unique product |

|

40% savings |

|

Stability |

|

Trust |

|

Individual approach

|

|

|

|

|

|

|

|

|

|

|

Official dealers of Sotras, Noitech, Filtrec

|

|

Exclusive partnerships with manufacturers give us the possibility to deliver the goods at the lowest prices |

|

6 years of successful work, hundreds of satisfied clients and our own production

|

|

We do not have occasional customers - everyone becomes part of a team of leaders! |

|

Individual approach for each client |