Home → Separators → Filters → Adsorption Dryers

Refrigerated Air Dryers from NEW FILTER

Refrigeration dryer is used in pneumatic

systems, compressed air, where the fluid temperature after the dryer doesn't

drop below the dew point temperature, guaranteed by dryer (+ 3°C).

In practice this means that if the air

system is in a heated room with air temperatures of + 5°C, then refrigerated

dryers provide no condensate in the obtained compressed air.

Discover the most interesting offers!

Discover the most interesting offers!

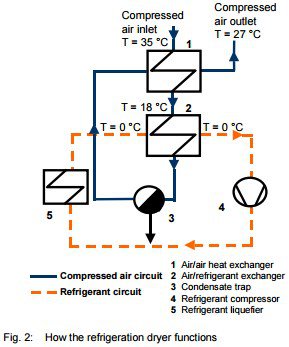

The operating principle of refrigeration

dryer

The refrigeration dryer extracts the water vapour contained in the compressed air. To achieve this, the compressed air is cooled in a heat exchanger system. Water and oil vapour are  extracted by condensation, oil by coagulation and coalescense.

extracted by condensation, oil by coagulation and coalescense.

The design of the refrigeration dryer

compressed air - it three-flow heat exchanger, which has a forced cooling air

from the fans gathered in a "pipe in pipe".

The whole mechanism is mounted in the open

air. The special structure of heat exchanger ensures smooth and stable

operation with any changes in climatic conditions.

The process of the compressed air cooling

takes place with the release of condensate that is separated automatically. As

a result, heating the dried air environment before its release to the pneumatic

pipe.

Dew point - setting unstable, which will

vary depending on the inlet air temperature and the environment. Usually index

is + 3 ° C.

But for specific conditions (length pneumatic

backbone enterprise, higher demands of consumers) after the refrigeration unit

may be mounted dryers deep dehydration.

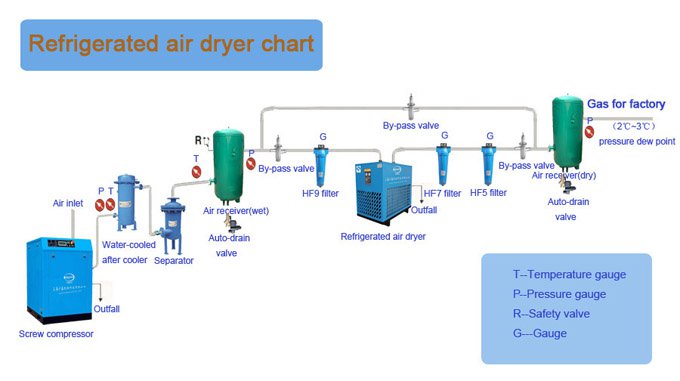

Pneumatic system

Dehumidifiers of the company «MTA»

Company «MTA» - is an Italian holding

company that leads the world in the production of high-tech refrigerated

compressed air dryers. The company's main activity - production of industrial

plants, the price of which the most competitive in the segment, as well as

liquid coolers (chillers).

The extensive product range and versatility

of this equipment fully meet the increasing demands of modern production, and

can significantly reduce energy consumption and improve the quality of

compressed air.

Ukrainian market of industrial

dehumidifiers «MTA» represented by two lines - refrigeration and adsorption

dryers types. Performance parameters have no analogues in Ukraine.

Product range of compressed air dryers

The dryers version DryPower, as in standard

compressors, compressed air is used to increase the efficiency of the heat

exchanger just two: air-to-refrigerant and air-to-air. Heat exchangers in the

lineup DryPower represent a complex of several heat exchangers, which are

called DRYMODULE.

DRYMODULE - is plate-tube heat exchanger,

which is composed of copper tubes and plates. It is a one-piece unit that

combines in its structure air-air heat exchanger, which serves for pre-cooling

and moisture separation section Freon air-heat exchanger, which is responsible

for final cooling

Controller TDC desiccant compressed

air

All compressed air dryers are equipped with

modern controllers TDC. This device allows you to perform several functions:

- Control of the dew point and heat mass.

- Prevention of compressed air temperature

drops below 0C at which the possible freezing of the heat exchanger and steam

trap.

- Full monitoring dryer performance and

monitoring indicators (three sensors, five input parameters).

- Monitoring of the condensate drain and

its programming (temporary or quantitative).

- Adjust the time of the opening

condensate drain valve

Why choose us?

..........

|

Unique product |

|

40% savings |

|

Stability |

|

Trust |

|

Individual approach

|

|

|

|

|

|

|

|

|

|

|

Official dealers of Sotras, Noitech, Filtrec

|

|

Exclusive partnerships with manufacturers give us the possibility to deliver the goods at the lowest prices |

|

6 years of successful work, hundreds of satisfied clients and our own production

|

|

We do not have occasional customers - everyone becomes part of a team of leaders! |

|

Individual approach for each client |