Home → EDM filters

Filters for Erosion Machines up to 150 mm

When EDM processing of parts of the

material often spreads beyond the work area. This is caused by melting, heating

and evaporation appearance of an electric discharge.  Therefore insulator

performs several functions: parts and insulates the electrodes, remove

cuttings, cool surface during processing.

Therefore insulator

performs several functions: parts and insulates the electrodes, remove

cuttings, cool surface during processing.

Also dielectric plays a key role when

flushing the working gap. This in turn determines the accurate of detail, the

amount of sludge as well as the cleanliness of the surface of the part itself.

The advantages of using the filter:

Х processing reliability;

Х high-quality dielectric filter;

Х coordinated and smooth operation of the

machine;

Х greater productivity.

Cleaning dielectric - a requirement that

affects the improvement of the quality and effectiveness of the preservation of

the use of EDM, copy-piercing machine, etc. It is therefore important to

choose the right EDM filter.

|

|

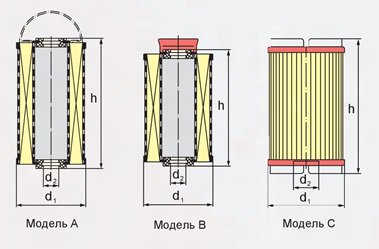

Model

|

Filtration layer area [sm2] |

Dimensions, mm

|

Filtration rate [µm] |

Flow direction |

|

|

| d1 | d2 | h |

|

| | H 1096 | A | 9300 | 100 | 22 | 202 | 42127 | in the center

| | H 15135n | B | 17900 | 150 | 32 | 252 | 10 | in the center | | H 15135Pn | B | 21200 | 150 | 32 | 252 | 42127 | in the center | | H 15190 | B | 20500 | 150 | 32 | 364 | 10 | in the center | | H 15190/6 | B | 27500 | 150 | 32 | 364 | 42127 | in the center | | H 15190/11 | B | 27500 | 150 | 32 | 364 | 42127 | in the center | | H 15190/12 | B | 21600 | 150 | 32 | 364 | 25 | in the center | | H 15190/14 | B | 27500 | 150 | 32 | 364 | 42127 | in the center | | H 15190/16 | C | 31000 | 150 | 32 | 375 | 42127 | in the center | | E-Line | C | 27000 | 150 | 32 | 375 | 42127 | in the center | | H 15475 | B | 47000 | 150 | 32 | 364 | 42127 | in the center | | H 15475/1 | C | 45320 | 150 | 32 | 375 | 42127 | in the center |

|